This week Wico has delivered the electrical cabinets for the phase 1 of an industrial freezing facility.

Know the electrical cabinets for industrial freezing system

These cabinets feed, protect and control the different equipment and sensors of an industrial freezing system. Data from pressure, temperature, etc. sensors gathered through a PLC gives us the necessary information about the process to command automatically the different system components (pumps, ventilators, compressors, etc.). Through an HDMI display all the information is available on a visual and intuitive way allowing an exhaustive control over it.

All the information is sent to a SCADA system where it is processed for a precise knowledge and control of the facility allowing a fast detection of faults and disturbances in the system.

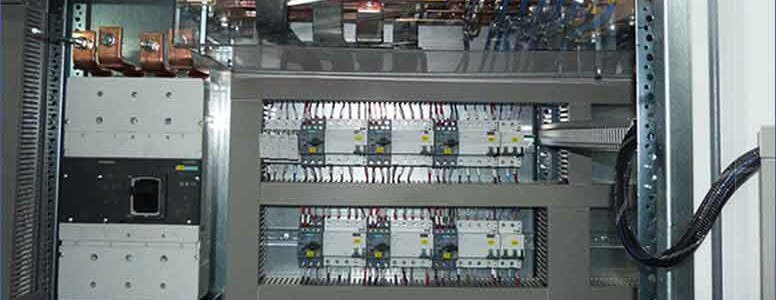

How are the electrical cabinets for industrial freezing system?

The cabinets have three power incomes of 800A. They fed two 315kW compressors driven through soft starters with oil pump and two heating resistors for each compressor. Manoeuvres were supervised by Prevenda® safety relays.

2 Evaporative condensers

each one of them including:

● 2 Ventilators driver through variable speed drive of 7.5kW

● 1 Water pump of 4kW

● 2 water tank heating resistors.

2 Glycol pumps of 45kW

Powered through soft starter.

Control system with a S7/1500 Siemens® PLC.

Composed by:

● 64 digital inputs.

● 32 digital outputs

● 48 analogue inputs.

● 8 Analogue outputs.

● Ethernet switch of 5 ports.

● 15” Display with touch interface

● 4 channel electronic protection device

All these components, installed in the electrical cabinets, are necessary to control the correct operation of the different transformation processes that take place in the industrial freezing facilities. A fit control system is essential for maintaining the delicate food freezing and preservation processes that are carried out.